- Преподавателю

- Иностранные языки

- Методическая разработка урока по английскому языку Types and composition of frozen desserts

Методическая разработка урока по английскому языку Types and composition of frozen desserts

| Раздел | Иностранные языки |

| Класс | - |

| Тип | Другие методич. материалы |

| Автор | Карибаева Г.И. |

| Дата | 13.12.2015 |

| Формат | doc |

| Изображения | Есть |

Сабақтың жоспары

План урока

Пән

Предмет

Prof. Engl.

Күні

дата

сабақтың №

№ занятия

Топ

группа

Тақырып Тема

Types and composition of frozen desserts.

МақсатЦели

Білімділік Дидактическая •to fasten lexical and writing skills on the topic

Дамытушылық Развивающая to develop monologue speech

ТәрбиелікВоспитывающая to bring up interest in the study of English culture.

Сабақтын типі (тұрпаты)

Тип урока

Lesson formation of writing skills.

Сабақтын әдісі

Метод обучения

Practical method.Collage.

Корнекілік

Оснащение

Text,tasks

Сабақтын барысы Ход урока

1. Бағдарлану - мотивациялық блок

Мотивационно - ориентировочный блок

Сабақтың тақырыбын шығу, жазу

Выход на тему, запись темы урока

Good morning, boys and girls! Nice to meet you! Sit down, please! What can you say about frozen desserts.?

Оқу мақсатын қою

Постановка цели, задач урока

formation of writing skills.

Сабақтың барысымен танысу Знакомство с ходом урока

Білім жаңғыртуы

Актуализация знаний

Types and composition of frozen desserts.

2. Жана материалды мазмұндау (баяндау) Изложение нового материала

Read and translate: Types and composition of frozen desserts

By varying quantities of main ingredients, numerous types of frozen dairy desserts can be produced Ice cream and ice milk. Major components of ice cream are known to be milk fat, nonfat milk solids, sugar, stabilizer, and flavouring. There exist a wide range for producers to vary content of both milk fat and nonfat milk solids, the quantity of one component being increased, thequantity of the other being decreased. Ice cream has the highest fat content, ranging from 10 to 20 percent.

Frozen custard, or French ice cream, is basically the same formula as ice cream except that in finished form it must contain at least 1.4 percent egg yolk2 solids.

Plain ice creams contain colouring and flavouring ingredients (such as vanilla, coffee and maple syrup) no more than 5 percent of their unfrozen volume Ice milk may be more commonly called "light" or "reduced-fat"4 ice cream. It contains between 2 and 7 percent milk fat and at least 11 percent total milk solids.

The first step in ice cream making is formulating a suitable mix, the latter being composed of a combination of dairy ingredients, such as fresh milk and cream, frozen cream, condensed or dried skim, buttermilk, dairy whey, or whey protein concentrate. Sugars may include sucrose, corn syrup, honey, and other syrups. Stabilizers and emulsifiers are added in small amounts to help prevent formation of ice crystals, particularly during temperature fluctuations in storage.

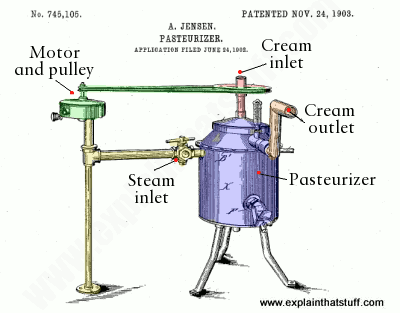

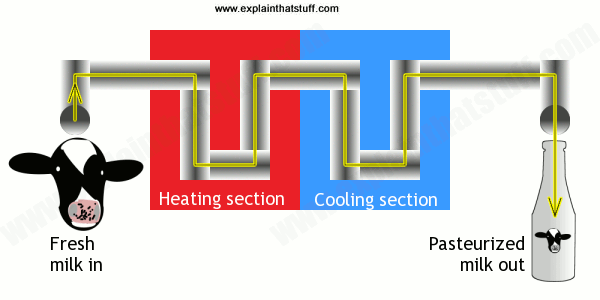

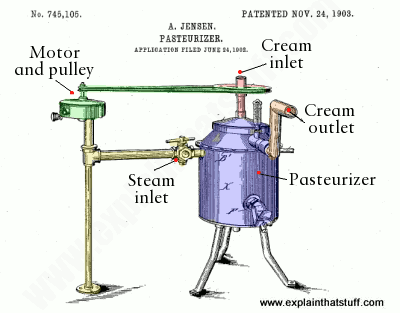

The ice cream mix is pasteurized at no less than 79°C for 25 seconds. The heated mix is typically homogenized in order to assure a smoother body and texture.

After homogenization, the hot mix is quickly cooled to 4.4°C. The mix must age at this temperature for at least four hours to allow the fat to solidify and fat globules to clump1. This ageing process results in quicker freezing and a smoother product.

Semifrozen ice cream leaving the freezer at a temperature between -9° and -5°C is placed in a suitable container and conveyed to a blast freezer4, where temperatures are in the range of -29° to -34°C. Rapid freezing at this stage prevents the formation of large ice crystals and favours a smooth body and texture.

Much of the appeal of ice cream comes from the variety of standard mixes and flavours available throughout the year. Most ice cream manufacturers make a standard mix consisting of milk, cream, sugars, and stabilizers, to which flavours may be added just prior to freezing. There exist various types of flavours, such as high-volume flavours (vanilla, chocolate, strawberry), with large particles (fruit, nuts, cookies, or candy parts), so they are added at different stages of the process.Being kept below -23° C and protected from temperature fluctuations, ice cream and other frozen desserts require no preservatives and have long shelf lives. Airtight6 packaging materials have made it possible to store frozen products for six months or longer without loss of flavour or body and texture.

Sherbets. They are characterized by a sweet but tart flavour and a low content of total milk solids (usually 3 to 5 percent).) Most standards require between 1 and 2 percent milk fat and between 2 and 5 percent total milk solids. Sherbet contains considerably more sugar and less air than ice cream (the target overrun is 30 to 40 percent), and therefore it is heavier and often contains more calories per serving.Ices. Being similar to sherbet, but containing no milk solids, water ices are usually composed of sugar (30 percent), fruit juice (20 percent), flavouring, colour, stabilizer (0.2 to 0.6 percent), citric acid, and water.

Overrun in ices should be approximately 30 percent.

3. Рефлексия бақылау блогыРефлексивно - оценочный блок

Білімдерін бекіту

Закрепление знаний

Answer the questions:

1) How does condensed milk differ from evaporated milk in the percentage of total milk solids and milk fat?

2) Which type of milk product (condensed/evaporated/dried) can be stored longer?

3) What kinds of dairy products can be dried?

4) What are the most desirable characteristics of frozen dessert?

5) What is the difference between plain and bulky ice creams.

6) What are the characteristics of sherbets?

7) What are ices composed of?

8) What are the steps of ice cream manufacture process?

Нәтижелерді жинақтап, қортындылау

Обобщение результатов, подведение итогов Conclusion of the lesson.

Рефлексия Collage.

Үй тапсырмасы

Домашнее задание retelling the text

қолы ___________________

подпись ________________

Read and translate: Types and composition of frozen desserts

By varying quantities of main ingredients, numerous types of frozen dairy desserts can be produced Ice cream and ice milk. Major components of ice cream are known to be milk fat, nonfat milk solids, sugar, stabilizer, and flavouring. There exist a wide range for producers to vary content of both milk fat and nonfat milk solids, the quantity of one component being increased, thequantity of the other being decreased. Ice cream has the highest fat content, ranging from 10 to 20 percent.

Frozen custard, or French ice cream, is basically the same formula as ice cream except that in finished form it must contain at least 1.4 percent egg yolk2 solids.

Plain ice creams contain colouring and flavouring ingredients (such as vanilla, coffee and maple syrup) no more than 5 percent of their unfrozen volume Ice milk may be more commonly called "light" or "reduced-fat"4 ice cream. It contains between 2 and 7 percent milk fat and at least 11 percent total milk solids.

The first step in ice cream making is formulating a suitable mix, the latter being composed of a combination of dairy ingredients, such as fresh milk and cream, frozen cream, condensed or dried skim, buttermilk, dairy whey, or whey protein concentrate. Sugars may include sucrose, corn syrup, honey, and other syrups. Stabilizers and emulsifiers are added in small amounts to help prevent formation of ice crystals, particularly during temperature fluctuations in storage.

The ice cream mix is pasteurized at no less than 79°C for 25 seconds. The heated mix is typically homogenized in order to assure a smoother body and texture.

After homogenization, the hot mix is quickly cooled to 4.4°C. The mix must age at this temperature for at least four hours to allow the fat to solidify and fat globules to clump1. This ageing process results in quicker freezing and a smoother product.

Semifrozen ice cream leaving the freezer at a temperature between -9° and -5°C is placed in a suitable container and conveyed to a blast freezer4, where temperatures are in the range of -29° to -34°C. Rapid freezing at this stage prevents the formation of large ice crystals and favours a smooth body and texture.

Much of the appeal of ice cream comes from the variety of standard mixes and flavours available throughout the year. Most ice cream manufacturers make a standard mix consisting of milk, cream, sugars, and stabilizers, to which flavours may be added just prior to freezing. There exist various types of flavours, such as high-volume flavours (vanilla, chocolate, strawberry), with large particles (fruit, nuts, cookies, or candy parts), so they are added at different stages of the process.Being kept below -23° C and protected from temperature fluctuations, ice cream and other frozen desserts require no preservatives and have long shelf lives. Airtight6 packaging materials have made it possible to store frozen products for six months or longer without loss of flavour or body and texture.

Sherbets. They are characterized by a sweet but tart flavour and a low content of total milk solids (usually 3 to 5 percent).) Most standards require between 1 and 2 percent milk fat and between 2 and 5 percent total milk solids. Sherbet contains considerably more sugar and less air than ice cream (the target overrun is 30 to 40 percent), and therefore it is heavier and often contains more calories per serving.Ices. Being similar to sherbet, but containing no milk solids, water ices are usually composed of sugar (30 percent), fruit juice (20 percent), flavouring, colour, stabilizer (0.2 to 0.6 percent), citric acid, and water.

Overrun in ices should be approximately 30 percent.

Answer the questions:

1) How does condensed milk differ from evaporated milk in the percentage of total milk solids and milk fat?2) Which type of milk product (condensed/evaporated/dried) can be stored longer?

3) What kinds of dairy products can be dried?4) What are the most desirable characteristics of frozen dessert?5) What is the difference between plain and bulky ice creams.6) What are the characteristics of sherbets?7) What are ices composed of?8) What are the steps of ice cream manufacture process?

Types of Frozen Desserts

Ice cream and frozen desserts come in many flavors and types with numerous delicious choices. Whether the flavor is vanilla, chocolate, cookie dough or chocolate chip, ice cream and its related products share certain basic characteristics that are often unknown or misunderstood by us.

Frozen desserts come in many forms. Each of the following types has its own definition, and many are standardized by federal regulations:

Ice Cream

Ice Cream consists of a mixture of dairy ingredients such as milk and nonfat milk, and ingredients for sweetening and flavoring, such as extracts, fruits, nuts and chocolate chips. Functional ingredients, such as stabilizers and emulsifiers, are often included to promote proper texture and enhance the eating experience. By federal law, ice cream must contain at least 10 percent milkfat, before the addition of bulky ingredients, and must weigh a minimum of 4.5 pounds to the gallon.

Frozen Custard or French Ice Cream

Frozen Custard or French Ice Cream must also contain a minimum of 10 percent milkfat, as well as at least 1.4 percent egg yolk solids.

Sherbets

Sherbets have a milkfat content of between 1 and 2 percent, and a slightly higher sweetener content than ice cream. Sherbet weighs a minimum of 6 pounds to the gallon and is flavored either with fruit or other similar ingredients.

Gelato

Gelato has an intense flavor and is served in a semi-frozen state that is similar to "soft serve" ice cream. Italian-style gelato is more dense than ice cream, since it has less air. Typically, gelato has more milk than cream, if any, and also contains sweeteners, egg yolks and flavoring.

Sorbet and Water Ices

Sorbet and Water Ices are similar to sherbets, but contain no dairy ingredients.

Quiescently Frozen Confection

A Quiescently Frozen Confection is a frozen novelty such as a water ice novelty on a stick (e.g. Popsicles).

Frozen Yogurt

Frozen Yogurt consists of a mixture of dairy ingredients such as milk and nonfat milk which have been cultured, as well as ingredients for sweetening and flavoring.

Novelties

Novelties are separately packaged single servings of a frozen dessert (e.g. ice cream sandwiches, fudge sticks and juice bars) that may or may not contain dairy ingredients.

July is National Ice Cream Month

July was designation as National Ice Cream Month by President Ronald Reagan in 1984 and the third Sunday of the month as National Ice Cream Day. President Reagan recognized America's appeal for ice cream -- ice cream is enjoyed by ninety percent of our nation's population -- when making this designation. He stated that these two events should be observed with "appropriate ceremonies and activities."

The United States ice cream industry generates more than 21 billion dollars in annual sales and provides thousands of jobs for our citizens. About 9 percent of all the milk produced by United States dairy farmers is used to produce ice cream, contributing significantly to the economic well-being of the nation's dairy industry.

From Karen's Kitchen has a wonderful selection of recipes for Ice Cream Desserts, Ice Cream Cakes,Ice Cream Pies and Milkshakes to celebrate these two events.

Popular Ice Cream Trends

Popular flavors

Vanilla continues to be America's favorite flavor in ice cream and novelties. This flavor is the most versatile, mixing well with toppings, drinks and bakery desserts. America's top five favorite individual flavors are vanilla, chocolate, butter pecan, strawberry and chocolate chip mint.

Manufacturers, scoop shops and chefs constantly are creating new and exciting flavors for their customers. To keep us looking to see what's next in the freezer case, individual processors often release limited time "seasonal" flavors, such as gingerbread, peppermint or caramel ice cream for the November/December holidays.

Healthy alternatives

While the majority of ice cream products have long been regular-fat products, processors continue to diversify their lines of frozen desserts in order to fit into various lifestyles -- often called "better for you" products. There are now an array of frozen desserts to fit specific dietary needs or wants, such as reduced-fat, fat-free, low-carb, "no sugar added," added calcium or other nutrients, or lactose-free ice cream. Novelty/single-serving products are also an important part of this trend, as some of us prefer the pre-packaged portion when counting calories, carbs or fat grams.

However, most of us are looking for an indulgence when eating ice cream. Therefore, ice cream manufacturers make sure to offer a full selection of premium and superpremium products in innovative flavors and with such mix-ins as cookies, brownies, candies and cake.

Popular brand ingredients added to ice cream

Another important trend for ice cream is the continuing popularity of popular companion products being added to ice cream. There has been an increase in the number of new ice cream products that use ingredients from well-known candy, cookie, fruit and flavoring manufacturers. In particular, novelty manufacturers have placed a strong emphasis on adding popular candy flavors. And, some ice cream manufacturers have teamed up in recent years with popular coffee and chocolate brands to create "ultrapremium" products. Signs indicate that this trend will continue in the future.

Storing And Handling Ice Cream

Ice cream is a perishable product and should be treated carefully. When frozen desserts are exposed to temperatures above 10°F (-12°C), the ice cream's body, texture and flavor are subject to adverse changes. Although homemade and individual manufacturers' recipes yield ice cream of varying consistency and flavor, all ice cream will be affected if improperly handled or stored.

Because of the fluctuating temperatures in most home freezers, if you follow these tips, you will be able to enjoy your ice cream within a month of making at home or purchasing from the supermarket.

The following suggestions on the proper handling and storage of ice cream and frozen desserts will help you enjoy America's favorite treat to the fullest.

At the store

-

Make the ice cream aisle your last stop during your trip to the supermarket.

-

Check the temperature of your grocer's freezer case. it should not be above -20°F (-29°C). If kept at a proper temperature, ice cream will be thoroughly frozen and will feel hard to the touch. If the ice cream is soft, you should bring it to the attention of the store manager.

-

In an open top freezer case, always select ice cream and frozen treats stored below the freezer line.

-

Put ice cream products in the separate section of your grocery cart, or place on top of other groceries.

-

Insulate ice cream products for the ride home. When your groceries are packed, request a freezer bag or additional brown paper bag to insulate your ice cream. Some store are now selling insulated grocery bags for reuse. Use these type of bags for all of your frozen groceries to keep them all frozen.

-

Make the grocery store or ice cream parlor your last errand before going home. This will avoid your ice cream from sitting in a warm car while you are making other stops.

At home

-

Do not allow ice cream to repeatedly soften and re-freeze. When the small ice crystals in ice cream melt and re-freeze, they can eventually turn into large, unpalatable lumps.

-

Your freezer should be set at between -5°F and 0°F (-21°C and -18°C). The ideal serving range is between 6°F and 10°F (-14°C and -12°C).

-

Store ice cream in the main compartment of the freezer. Since the door of your freezer is repeatedly open and shut, do not store ice cream in the freezer door, where ice cream can be subject to more fluctuating temperatures.

-

Keep the ice cream container lid tightly closed when storing in the freezer and make sure the ice cream is covered with plastic wrap or the ice cream carton's protective covering before closing the lid.

-

Don't store ice cream alongside uncovered foods; odors may penetrate the ice cream and affect its flavor. If this cannot be prevented, place ice cream or ice cream carton in a plastic container with a tight lid.

By following these simple suggestions, you can help keep your ice cream and other frozen dessert treats stay as they were when first made -- attractive and delicious!

Tips for Successful Homemade Ice Cream

Ice Cream is enjoyed by people all over the world. While it is sometimes easier and less-expensive to purchase ice cream from your local supermarket, there is just something extra-special about making homemade ice cream that you can't get from the supermarket.

Ice Cream is enjoyed by people all over the world. While it is sometimes easier and less-expensive to purchase ice cream from your local supermarket, there is just something extra-special about making homemade ice cream that you can't get from the supermarket.

With just a few ingredients -- cream, milk, eggs, sugar, and flavorings -- you can make this fabulous treat at home. Here are some helpful tips to make your homemade ice cream successful.

Make your ice cream the day before serving.

If possible, make your ice cream the day before you plan on serving it. This will allow plenty of time for the ice cream to harden in the freezer, resulting in a smoother and creamier ice cream.

Pre-freeze ice maker bowls

Since the bowls of most ice cream makers take at least 24 hours to freeze, keep them tightly wrapped in a plastic bag in the freezer. Then they will always be ready when you want to make ice cream.

Use only 3 to 4 tablespoons of hot liquid when tempering egg yolks

Regardless of the recipe's instructions, when tempering egg yolks for custard-based ice creams, only pour 3 or 4 tablespoons of hot cream into the yolks before slowly adding them back into the ice cream mixture to avoid the eggs from scrambling.

Use alcohol in moderation in your ice cream mixture

Only use up to 1/4 cup of alcohol per 1 quart of ice cream. Any more will interfere with the ice cream's ability to freeze. To prevent loss of flavor, add the alcohol after the ice cream mixture has cooled.

Add in your extracts when ice cream has cooled

For the best flavor, add the extracts or flavoring oils (vanilla, almond, maple, orange, peppermint, etc.) after the ice cream mixture has cooled.

Strain custard-based mixture before processing

When making egg-based or custard-style ice cream, strain the completed mixture before chilling to remove small chunks of egg that may have scrambled during cooking.

Keep the ice cream mixture cold

Always, place your ice cream mixture in a container and chill it in the refrigerator for 8 hours or overnight. The ice cream mixture freezes quicker and better if you start with a cold mixture in your ice cream maker.

Fill ice cream maker three-quarters full

For best results, only fill the ice cream maker three-quarters full. It is important not to overfill it. If there is too much mixture in the bowl, it will not aerate properly when processed.

Add mix-in just before the churning has completed

To maintain the texture of your mix-ins (chocolate chips, nut, candy pieces), add them during the last minute of churning. The ice cream should already be done, you just want to distribute them evenly into the ice cream.

Toast mix-ins just before adding them to the ice cream

Toast nuts and coconut slivers or cookies, brownies and cakes before adding to your ice cream to extract their full flavor. Using toasted mix-ins help keep their crunchiness and prevents them from becoming soggy in the ice cream.

Store processed ice cream in rectangular containers

Once your ice cream has been processed, store it in the freezer in a shallow, flat, rectangular container. This will promote an even consistency to your ice cream.

Store processed ice cream in a container with a tight fitting lid

Use a rectangular container with a tight fitting lid to prevent odors in the freezer from changing the flavor of the ice cream.

Keep your ice cream covered with plastic wrap

Once the processed ice cream has been placed in a storage container, place a layer of plastic wrap or wax paper over the top of the ice cream before closing the lid. This will prevent ice crystals from forming on your ice cream.

Store ice cream in the main compartment of your freezer

Homemade ice cream is best stored in the main compartment of your freezer where the temperature remains mostly consist. This will keep the ice cream from partially thawing and re-freezing when the freezer door is opened which will help prevent ice crystals from forming on the ice cream.

Consumer your homemade ice cream within a week

Homemade ice cream keeps well in your freezer up to a week. After that, it will begin to lose its creamy texture and flavor.

Сабақтың жоспары

План урока

Пән

Предмет

Prof. Engl.

Күні

дата

сабақтың №

№ занятия

Топ

группа

Тақырып Тема

Evaporation of milk.

МақсатЦели

Білімділік Дидактическая •to fasten lexical and writing skills on the topic

Дамытушылық Развивающая to develop monologue speech

ТәрбиелікВоспитывающая to bring up interest in the study of English culture.

Сабақтын типі (тұрпаты)

Тип урока

Lesson formation of writing skills.

Сабақтын әдісі

Метод обучения

Practical method.Collage.

Корнекілік

Оснащение

Text,tasks

Сабақтын барысы Ход урока

1. Бағдарлану - мотивациялық блок

Мотивационно - ориентировочный блок

Сабақтың тақырыбын шығу, жазу

Выход на тему, запись темы урока

Good morning, boys and girls! Nice to meet you! Sit down, please! What can you say about Evaporation of milk.?

Оқу мақсатын қою

Постановка цели, задач урока

formation of writing skills.

Сабақтың барысымен танысу Знакомство с ходом урока

Білім жаңғыртуы

Актуализация знаний

Evaporation of milk.

2. Жана материалды мазмұндау (баяндау) Изложение нового материала

Read and translate: Evaporation of milk.

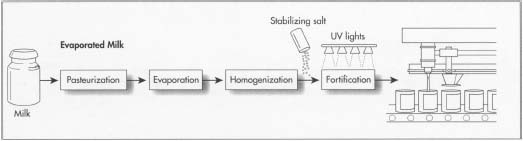

Evaporated milk is a milk product, usually sold in cans, that is made by removing about 60 percent of the water from ordinary milk.

Evaporated milk can be made from both whole milk or skim milk. In either case, the milk is homogenized and then the water is removed by gently heating it. The evaporated milk product is sealed in cans which are then heated to kill any bacteria in the milk. Thus evaporated milk is actually sterile, which, combined with the fact that it is stored in airtight cans, gives it an extremely long shelf life.

Canned evaporated milk can be stored for at least a year, although you should always check the use-by date printed on the can. Also, don't use any cans that are rusted, dented or bulging. Once you open the can, you should store the milk in the refrigerator, preferably not in the original can but in a glass container, and use it within seven days.

Evaporated milk is enriched with vitamin D. The process of heating the evaporated milk in the cans imparts a slightly sweet flavor to the milk, and it's also just a bit darker in color than ordinary milk. Note that evaporated milk is not the same thing as condensed milk. Condensed milk is also reduced by 60 percent, but it is heavily sweetened and usually used in baking and desserts.

Evaporated milk can be used as a substitute for milk or cream, like in coffee and tea or poured over cereal. Evaporated milk can also be used in recipes that call for milk or cream, such as French toast, mashed potatoes or creamed vegetables like this creamed spinach recipe. You can also use evaporated milk in cream sauces like this basic white sauce.

You could also use evaporated milk for making the white gravy that accompanies this pork cutlet recipe.

Although you can usually use evaporated milk directly from the can in recipes that call for milk, you can convert evaporated milk to back to regular milk simply by diluting it with an equal part of water - so add half a cup of water to half a cup of evaporated milk.

Have a partial can of evaporated milk that you need to use up? Try these ideas:

-

use it in place of the milk or cream in recipes. It works especially well inmashed potatoes, macaroni and cheeseand cream soups

-

add it to coffee or tea for a special treat

-

use it in place of the water in bread recipes to boost the nutritional value

-

reconstitute it (by adding enough water to double the volume). Then, use it like regular milk

-

whip up a basic white sauce

Want to avoid leftovers in the future? Learn how to make your own evaporated milk, and you can make just what you need:

-

How to Make Evaporated Milk

A diagram showing the manufacturing steps involved in making evaporated milk.

A diagram showing the manufacturing steps involved in making evaporated milk.

Canadians have been counting on CarnationEvaporated Milk for

ore than 100 years to make delicious, nutritious treats and meals he whole family asks for again and again. And sinceCarnation Evaporated Milk is thicker and creamier than milk, it's a perfect lower-fat substitute for cream in most recipes.

Try one of these quick and easy recipes. You can tell us what you think by rating recipes. And if you're a member, you can also add a comment and mark your favourites so they're easy to find.

3. Рефлексия бақылау блогы

Рефлексивно - оценочный блок

Білімдерін бекіту

Закрепление знаний

What does the Invisible Man drink at snack time?

Ответ: Evaporated milk

What did the chocolate bar say to the lollipop?

Ответ: Hello, sucker!

Where is the best place to see a man-eating fish?

Ответ: In a seafood restaurant.

What part of your body has the most rhythm?

Ответ: Your eardrums.

What kind of soda must you not drink?

Ответ: Baking soda.

Why are potatoes good detectives?

Ответ: Because they keep their eyes peeled.

What did the sock say to the foot?

Ответ: You are putting me on!

What clothing does a house wear?

Ответ: Address.

Can giraffes have babies?

Ответ: No, they only have giraffes!

What did Frankenstein say when a bolt of lightning hit him?

Ответ: Thanks, I needed that.

If you dropped a tomato on your toe, would it hurt much?

Ответ: Yes, if it was in a can.

Why does a dentist seem moody?

Ответ: Because he always looks down in the mouth

Why is an eye doctor like a teacher?

Ответ: They both test the pupils

What is both inside and outside a house?

Ответ: Front door.

What can't be burned in fire, nor drowned in water?

Ответ: Ice.

There is a six letter word of which la is the middle, is the beginning, and the ending. What is the word?

Ответ: Island.

What is a little dog's favorite drink?

Ответ: Pupsi-cola

What has a big mouth, yet never speaks?

Ответ: A jar

What is the first thing you do in the morning?

Ответ: Wake up

Нәтижелерді жинақтап, қортындылау

Обобщение результатов, подведение итогов Conclusion of the lesson.

Рефлексия

Рефлексия Collage.

Үй тапсырмасы

Домашнее задание retelling the text

қолы ___________________

подпись ________________

Сабақтың жоспары

План урока

Пән

Предмет

Prof. Engl.

Күні

дата

сабақтың №

№ занятия

Топ

группа

Тақырып

Тема

Mechanization in livestock:milking machines..

МақсатЦели

Білімділік Дидактическая •to fasten lexical and a writing skills on the topic

Дамытушылық Развивающая to develop monologue speech

ТәрбиелікВоспитывающая to bring up interest in the study of English culture.

Сабақтын типі (тұрпаты)

Тип урока

Lesson formation of reading skills.

Сабақтын әдісі

Метод обучения

Practical method.Collage.

Корнекілік

Оснащение

Text,tasks

Сабақтын барысы Ход урока

1. Бағдарлану - мотивациялық блок

Мотивационно - ориентировочный блок

Сабақтың тақырыбын шығу, жазу

Выход на тему, запись темы урока

Good morning, boys and girls! Nice to meet you! Sit down, please! What can you say about Mechanization in livestock?

Оқу мақсатын қою

Постановка цели, задач урока

formation of writing skills.

Сабақтың барысымен танысу Знакомство с ходом урока

Білім жаңғыртуы

Актуализация знаний

Mechanization in livestock

Mechanization in livestock

2. Жана материалды мазмұндау (баяндау) Изложение нового материала

Read and translate:Mechanization in livestock raising

Further increase in animal productivity is achieved both by the introduction of new machinery and by wider electrification and automation of different processes on livestock farms.

Some kinds of livestock equipment are almost completely automatic, thus eliminating most of the hand labour. Many farms are using now automatic waterers which provide water to livestock at all times. At the press of the button silage unloaders remove silage from the silo and drop it into the conveyer that carries the silage to the feed troughs. The feeding of grain and hay to dairy cattle has also been almost completely mechanized on some farms. On most farms manure is collected and transported automatically.

Different machines are now being used which permit a better digestion of various feeds by livestock. For instance, grain grinders, feed mixers, forage cutters increase the feeding value of grain, roughages and other feeds.

Milk pipelines connected to milking machines carry the milk to milk tanks where it is automatically cooled to the proper temperature.

In some poultry houses time clock devices are installed so that chickens can be fed automatically at the desired time of the day. On many poultry farms eggs are cleaned, graded and packed primarily by automation.

3. Рефлексия бақылау блогы

Рефлексивно - оценочный блок

Білімдерін бекіту

Закрепление знаний

Learn the words.

automatic waterer - автопоилка to carry - тащить, перевозить digestion - переваривание, усваивание feed mixer - кормосмеситель feed trough - кормушка forage cutter - корморезка to grade - сортировать grain grinder - зернодробилка milk pipeline - молокопровод milk tank - цистерна для молока to remove вынимать, удалять silo - силосная башня, яма

1.Say in Russian:

a) что даёт механизация в области животноводства?;

b) какие процессы наиболее полно механизированы в животноводстве?

Обоснуйте свои ответы предложениями из текста.

2. Answer the following questions:

1. How is higher productivity achieved?

2. .Does mechanization eliminate hand labour?

3. What do silage unloaders do?

4. Is manure collected automatically?

5. What machines increase the feeding value of feeds?

6. What processes are mechanized in poultry breeding?

Нәтижелерді жинақтап, қортындылау

Обобщение результатов, подведение итогов Conclusion of the lesson.

Рефлексия

Рефлексия Collage.

Үй тапсырмасы

Домашнее задание retelling the text

қолы ___________________

подпись ________________

Сабақтың жоспары

План урока

Пән

Предмет

Prof. Engl.

Күні

дата

сабақтың №

№ занятия

Топ

группа

Тақырып Тема

Cooling and storage of milk.

МақсатЦели

Білімділік Дидактическая •to fasten lexical and a writing skills on the topic

Дамытушылық Развивающая to develop monologue speech

ТәрбиелікВоспитывающая to bring up interest in the study of English.

Сабақтын типі (тұрпаты)

Тип урока

Lesson formation of reading skills.

Сабақтын әдісі

Метод обучения

Practical method.Collage.

Корнекілік Оснащение

Text,tasks

Сабақтын барысы Ход урока

1. Бағдарлану - мотивациялық блок Мотивационно - ориентировочный блок

Сабақтың тақырыбын шығу, жазу

Выход на тему, запись темы урока

Good morning, boys and girls! Nice to meet you! Sit down, please! What can you say about Cooling and storage of milk.?

Оқу мақсатын қою

Постановка цели, задач урока

formation of writing skills.

Сабақтың барысымен танысу Знакомство с ходом урока

Білім жаңғыртуы Актуализация знаний

Cooling and storage of mil

k

k

2. Жана материалды мазмұндау (баяндау) Изложение нового материала

Read and translate: Cooling and storage of milk.

Storage of Milk: Importance and Methods of Cooling!

Importance:

Milk drawn from a healthy cow is sterile but it contains bacteria that have entered the teat canal through the teat opening. They are pushed out during milking process. The number of bacteria varies from animal to animal. For milk contains greater number of bacteria than stripping (Singh and Prasad, 1987).

Milk gets easily contaminated with dirt, bacteria and odours. Milk furnishes an excellent medium for the growth of bacteria, particularly when not properly cooled. They produce chemical changes rendering it unpalatable.

Pathogenic bacteria can also very well multiply in milk. Therefore, milk may serve as a medium for dissemination of infectious diseases. Hence the quality and conditions of production of milk can be judged on the basis of microbial contents.

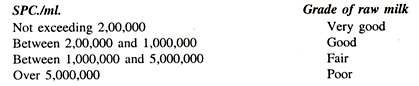

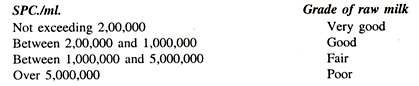

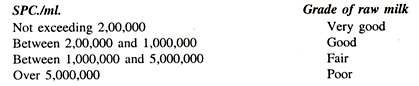

I.S. 1479 (Part III) 1982 prescribed the following standards for the bacteriological quality of raw milk:

Therefore great care in production and handling of milk is necessary to put it in the hands of consumers in a satisfactory condition.

Handling the Milk Prior To Storage:Milk should be removed to the milk house immediately after it is drawn because the contamination may also take place if it is left in the barn, the milk should then be strained into cans. If the cows are carefully milked, straining may not be necessary.

It is impossible to strain bacteria out of milk. However, it is desirable to filter the milk to remove hairs, particles of feed or bedding or dirt, etc. that may have into milk during the production. A single service pad type strainer may be used for this purpose.

Necessity of Cooling Milk before Storage:It is impossible to produce milk without some bacteria. Therefore efforts should be to prevent multiplication of the bacteria that have gained access.- This can be achieved by cooling the raw milk.

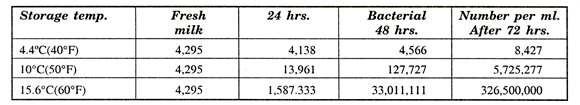

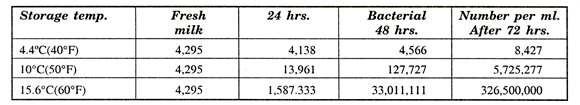

Principles and Practices of Dairy Farm Management:This is of utmost importance specially when considerable time lapses between production and pasteurization. Even before it is transported to long distances the rails is cooled. The influence of temperature of storage on the bacterial density in fresh milk as reported by Ayres et al. (1918) is given in Table 18.1.

Table 18.1: Bacterial Count in Fresh Milk of Storage (Average of 20 Samples from Cows Clean & Bedded, Small Top Pails, Sterile Utensils):

From the observations of Ayres et al. (1918) it is clear that milk should be stored at 4.5°C to arrest the growth of bacteria and milk will not become sour. Cooling to milk has a special significance in the tropical climate specially in summer. Therefore milk should be cooled to below 10°C. Freshly drawn milk is at about 38°C which is highly suited for bacterial growth.

Methods of Cooling:

1. Indigenous method:Milk venders who collect milk from villages are issued licence on the agreement that they will put the wet cloth around the can of milk to keep milk cool during the period of transportation by bicycle or cart, etc.

2. Scientific method:

There are four methods used under this. These are as follows:

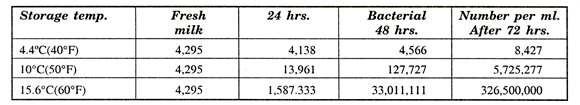

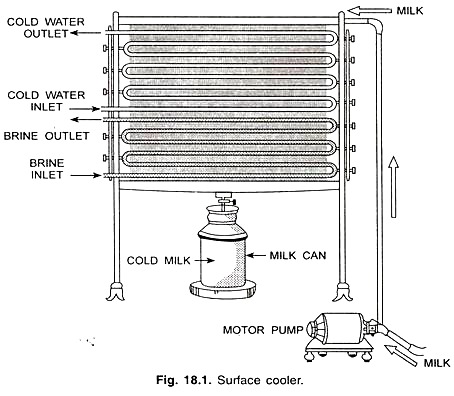

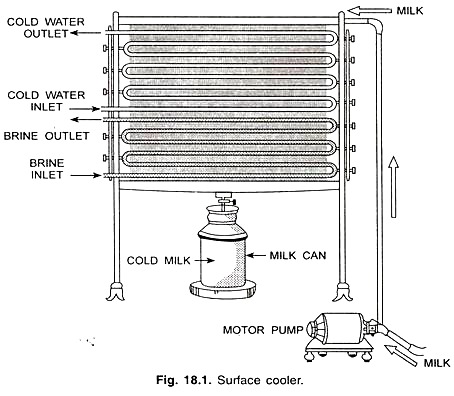

1. Use of surface coolers/surface tubular coolers. (See Fig. 18.1)

2. Cabinet coolers in vertical position.

3. Plate type chillers,

4. Double tube coolers.

The different cooling media used are as follows:

(a) Cold water to cool down pasteurized milk up to 15.5° to 21.1°C.

(b) Ammonia refrigerant to cool down milk up to 3.3°C to 4.3°C (35° to 40°F).

(c) Brine solution is effective in bringing temperature of milk to 3.3°C (35°F).

Storage of Milk in Tanks:

Modern storage tanks for milk are of two type's viz. horizontal and vertical cylindrical shape of 10,000 litre capacity. In countries of temperate climate where milk is not stored for more than 24 hrs. the insulation of tanks is not necessary. In tropical regions of warmer climate 7 to 10 cm cork insulation is desirable to maintain minimum temperature 4°C. Milk kept at low temperature will have longer keeping quality suitable for processing in dairy plant.

Objectives of having Bulk Milk Cooling Units:

1.To enhance the keeping quality of milk and also to avoid economic losses to farmers due to spillage/sourage of milk.

2.To produce improved quality products for export as well as to meet the domestic requirements.

3.To reduce the transportation cost by regulating transportation of the milk on alternative days and also through reduction in expenditure on purchase and maintenance of cans.

Thus,BMCUs provides a viable option for reducing the transportation cost as also maintaining the milk quality.

Beneficiaries of Bulk Milk Cooling Units (BMCUs) are Milk collection Agents,Village Milk Cooperative Societies of Cooperative Milk Union or Milk Collection Centers of private Dairies.

The operations involve collection and chilling of milk to a temperature of 4 Degrees C.

Advantages of using stainless steel Bulk Milk Cooler or Milk Chillers in modern dairy industry:

1.Elimination of souring/curdling of milk because of cooling at the collection center itself.

2.Adulteration of milk and spillage from cans can be eliminated during transport.

3.Transportation cost of milk can be brought down by regulating transportation to the main dairy either on alternative days or once in a day.

4.Saving of initial investment on purchase of cans and subsequent maintenance cost (Repairs, cleaning etc.) of those cans.

5.Improved quality of milk can be supplied to the main dairy to manufacture quality products for domestic as well as export markets.

6.Flexibility in milk collection time results in increase in volume of milk collected at the centers.

7.Farmers will get better returns for the quality of milk.

8.Chilling at the Main dairy can be avoided.

Economics of buying Bulk Milk Coolers:

Based on the various techno commercial parameters,the economics of the purchase of new Bulk Milk Coolers is very positive. The items of income include reduction in souring/curdling of milk, spillage and pilferage of milk, saving of expenditure on transportation, purchase and maintenance of cans and chilling cost received from the union while the expenditure includes the operational cost of cooler (fuel/power), repairs, maintenance and additional manpower.

3. Рефлексия бақылау блогы

Рефлексивно - оценочный блок

Білімдерін бекіту Закрепление знаний

Read and translate: Cooling and storage of milk.

Storage of Milk: Importance and Methods of Cooling!

KWL

Нәтижелерді жинақтап, қортындылау

Обобщение результатов, подведение итогов Conclusion of the lesson.

РефлексияCollage.

Үй тапсырмасы

Домашнее задание retelling the text

қолы ___________________

подпись ________________

Storage of Milk: Importance and Methods of Cooling!

Importance:Milk drawn from a healthy cow is sterile but it contains bacteria that have entered the teat canal through the teat opening. They are pushed out during milking process. The number of bacteria varies from animal to animal. For milk contains greater number of bacteria than stripping (Singh and Prasad, 1987).

Milk gets easily contaminated with dirt, bacteria and odours. Milk furnishes an excellent medium for the growth of bacteria, particularly when not properly cooled. They produce chemical changes rendering it unpalatable.

Pathogenic bacteria can also very well multiply in milk. Therefore, milk may serve as a medium for dissemination of infectious diseases. Hence the quality and conditions of production of milk can be judged on the basis of microbial contents.

I.S. 1479 (Part III) 1982 prescribed the following standards for the bacteriological quality of raw milk:

Therefore great care in production and handling of milk is necessary to put it in the hands of consumers in a satisfactory condition.

Handling the Milk Prior To Storage:Milk should be removed to the milk house immediately after it is drawn because the contamination may also take place if it is left in the barn, the milk should then be strained into cans. If the cows are carefully milked, straining may not be necessary.

It is impossible to strain bacteria out of milk. However, it is desirable to filter the milk to remove hairs, particles of feed or bedding or dirt, etc. that may have into milk during the production. A single service pad type strainer may be used for this purpose.

Necessity of Cooling Milk before Storage:It is impossible to produce milk without some bacteria. Therefore efforts should be to prevent multiplication of the bacteria that have gained access.- This can be achieved by cooling the raw milk.

Principles and Practices of Dairy Farm Management:This is of utmost importance specially when considerable time lapses between production and pasteurization. Even before it is transported to long distances the rails is cooled. The influence of temperature of storage on the bacterial density in fresh milk as reported by Ayres et al. (1918) is given in Table 18.1.

Table 18.1: Bacterial Count in Fresh Milk of Storage (Average of 20 Samples from Cows Clean & Bedded, Small Top Pails, Sterile Utensils):

From the observations of Ayres et al. (1918) it is clear that milk should be stored at 4.5°C to arrest the growth of bacteria and milk will not become sour. Cooling to milk has a special significance in the tropical climate specially in summer. Therefore milk should be cooled to below 10°C. Freshly drawn milk is at about 38°C which is highly suited for bacterial growth.

Methods of Cooling:1. Indigenous method:Milk venders who collect milk from villages are issued licence on the agreement that they will put the wet cloth around the can of milk to keep milk cool during the period of transportation by bicycle or cart, etc.

2. Scientific method:

There are four methods used under this. These are as follows:

1. Use of surface coolers/surface tubular coolers. (See Fig. 18.1) 2. Cabinet coolers in vertical position.3. Plate type chillers,4. Double tube coolers.

The different cooling media used are as follows:

(a) Cold water to cool down pasteurized milk up to 15.5° to 21.1°C.(b) Ammonia refrigerant to cool down milk up to 3.3°C to 4.3°C (35° to 40°F).(c) Brine solution is effective in bringing temperature of milk to 3.3°C (35°F).Storage of Milk in Tanks:Modern storage tanks for milk are of two type's viz. horizontal and vertical cylindrical shape of 10,000 litre capacity. In countries of temperate climate where milk is not stored for more than 24 hrs. the insulation of tanks is not necessary. In tropical regions of warmer climate 7 to 10 cm cork insulation is desirable to maintain minimum temperature 4°C. Milk kept at low temperature will have longer keeping quality suitable for processing in dairy plant.

Objectives of having Bulk Milk Cooling Units:

1.To enhance the keeping quality of milk and also to avoid economic losses to farmers due to spillage/sourage of milk.2.To produce improved quality products for export as well as to meet the domestic requirements.3.To reduce the transportation cost by regulating transportation of the milk on alternative days and also through reduction in expenditure on purchase and maintenance of cans.Thus,BMCUs provides a viable option for reducing the transportation cost as also maintaining the milk quality.Beneficiaries of Bulk Milk Cooling Units (BMCUs) are Milk collection Agents,Village Milk Cooperative Societies of Cooperative Milk Union or Milk Collection Centers of private Dairies.The operations involve collection and chilling of milk to a temperature of 4 Degrees C.

Advantages of using stainless steel Bulk Milk Cooler or Milk Chillers in modern dairy industry:1.Elimination of souring/curdling of milk because of cooling at the collection center itself.2.Adulteration of milk and spillage from cans can be eliminated during transport.

3.Transportation cost of milk can be brought down by regulating transportation to the main dairy either on alternative days or once in a day.4.Saving of initial investment on purchase of cans and subsequent maintenance cost (Repairs, cleaning etc.) of those cans.5.Improved quality of milk can be supplied to the main dairy to manufacture quality products for domestic as well as export markets.6.Flexibility in milk collection time results in increase in volume of milk collected at the centers.7.Farmers will get better returns for the quality of milk.8.Chilling at the Main dairy can be avoided.

Economics of buying Bulk Milk Coolers:Based on the various techno commercial parameters,the economics of the purchase of new Bulk Milk Coolers is very positive. The items of income include reduction in souring/curdling of milk, spillage and pilferage of milk, saving of expenditure on transportation, purchase and maintenance of cans and chilling cost received from the union while the expenditure includes the operational cost of cooler (fuel/power), repairs, maintenance and additional manpower.

Read and translate: Cooling and storage of milk.Storage of Milk: Importance and Methods of Cooling!

KWL

Storage of Milk: Importance and Methods of Cooling!

Importance:Milk drawn from a healthy cow is sterile but it contains bacteria that have entered the teat canal through the teat opening. They are pushed out during milking process. The number of bacteria varies from animal to animal. For milk contains greater number of bacteria than stripping (Singh and Prasad, 1987).

Milk gets easily contaminated with dirt, bacteria and odours. Milk furnishes an excellent medium for the growth of bacteria, particularly when not properly cooled. They produce chemical changes rendering it unpalatable.

Pathogenic bacteria can also very well multiply in milk. Therefore, milk may serve as a medium for dissemination of infectious diseases. Hence the quality and conditions of production of milk can be judged on the basis of microbial contents.

I.S. 1479 (Part III) 1982 prescribed the following standards for the bacteriological quality of raw milk:

Therefore great care in production and handling of milk is necessary to put it in the hands of consumers in a satisfactory condition.

Handling the Milk Prior To Storage:Milk should be removed to the milk house immediately after it is drawn because the contamination may also take place if it is left in the barn, the milk should then be strained into cans. If the cows are carefully milked, straining may not be necessary.

It is impossible to strain bacteria out of milk. However, it is desirable to filter the milk to remove hairs, particles of feed or bedding or dirt, etc. that may have into milk during the production. A single service pad type strainer may be used for this purpose.

Necessity of Cooling Milk before Storage:It is impossible to produce milk without some bacteria. Therefore efforts should be to prevent multiplication of the bacteria that have gained access.- This can be achieved by cooling the raw milk.

Principles and Practices of Dairy Farm Management:This is of utmost importance specially when considerable time lapses between production and pasteurization. Even before it is transported to long distances the rails is cooled. The influence of temperature of storage on the bacterial density in fresh milk as reported by Ayres et al. (1918) is given in Table 18.1.

Table 18.1: Bacterial Count in Fresh Milk of Storage (Average of 20 Samples from Cows Clean & Bedded, Small Top Pails, Sterile Utensils):

From the observations of Ayres et al. (1918) it is clear that milk should be stored at 4.5°C to arrest the growth of bacteria and milk will not become sour. Cooling to milk has a special significance in the tropical climate specially in summer. Therefore milk should be cooled to below 10°C. Freshly drawn milk is at about 38°C which is highly suited for bacterial growth.

Methods of Cooling:1. Indigenous method:Milk venders who collect milk from villages are issued licence on the agreement that they will put the wet cloth around the can of milk to keep milk cool during the period of transportation by bicycle or cart, etc.

2. Scientific method:

There are four methods used under this. These are as follows:

1. Use of surface coolers/surface tubular coolers. (See Fig. 18.1)2. Cabinet coolers in vertical position.3. Plate type chillers,4. Double tube coolers.

The different cooling media used are as follows:(a) Cold water to cool down pasteurized milk up to 15.5° to 21.1°C.(b) Ammonia refrigerant to cool down milk up to 3.3°C to 4.3°C (35° to 40°F).(c) Brine solution is effective in bringing temperature of milk to 3.3°C (35°F).

Storage of Milk in Tanks:Modern storage tanks for milk are of two type's viz. horizontal and vertical cylindrical shape of 10,000 litre capacity. In countries of temperate climate where milk is not stored for more than 24 hrs. the insulation of tanks is not necessary. In tropical regions of warmer climate 7 to 10 cm cork insulation is desirable to maintain minimum temperature 4°C. Milk kept at low temperature will have longer keeping quality suitable for processing in dairy plant.

Objectives of having Bulk Milk Cooling Units:

1.To enhance the keeping quality of milk and also to avoid economic losses to farmers due to spillage/sourage of milk.2.To produce improved quality products for export as well as to meet the domestic requirements.3.To reduce the transportation cost by regulating transportation of the milk on alternative days and also through reduction in expenditure on purchase and maintenance of cans.

Thus,BMCUs provides a viable option for reducing the transportation cost as also maintaining the milk quality.Beneficiaries of Bulk Milk Cooling Units (BMCUs) are Milk collection Agents,Village Milk Cooperative Societies of Cooperative Milk Union or Milk Collection Centers of private Dairies.The operations involve collection and chilling of milk to a temperature of 4 Degrees C.

Advantages of using stainless steel Bulk Milk Cooler or Milk Chillers in modern dairy industry:

1.Elimination of souring/curdling of milk because of cooling at the collection center itself. 2.Adulteration of milk and spillage from cans can be eliminated during transport. 3.Transportation cost of milk can be brought down by regulating transportation to the main dairy either on alternative days or once in a day.

4.Saving of initial investment on purchase of cans and subsequent maintenance cost (Repairs, cleaning etc.) of those cans.

5.Improved quality of milk can be supplied to the main dairy to manufacture quality products for domestic as well as export markets.

6.Flexibility in milk collection time results in increase in volume of milk collected at the centers.

7.Farmers will get better returns for the quality of milk.

8.Chilling at the Main dairy can be avoided.

Economics of buying Bulk Milk Coolers:

Based on the various techno commercial parameters,the economics of the purchase of new Bulk Milk Coolers is very positive. The items of income include reduction in souring/curdling of milk, spillage and pilferage of milk, saving of expenditure on transportation, purchase and maintenance of cans and chilling cost received from the union while the expenditure includes the operational cost of cooler (fuel/power), repairs, maintenance and additional manpower.

Being the world's largest producer and consumer of dairy products, India represents one of most lucrative dairy markets.

The Indian dairy industry is contributing significantly to the country's economy,besides improving the health standard by increasing the nutritional value of the food.

At 100 million tons of milk production, India is the highest milk producing country in the world. Almost half of milk produced in the country is consumed as raw milk and the rest converted into different dairy products.Since the processed dairy products lacks quality standards and hygiene value, country is unable to export dairy products in large measures. Therefore Indian Dairy industry is looking at Bulk Milk Coolers to reduce the temperature of the milk for minimizing growth of bacteria which in turn would improve shelf life of the milk.

When Milk is extracted,it is at around 37 Degrees C.It milk continues to remain at room temperature after extraction, bacterial growth will affect the quality of the milk.Only rapidly cooling milk immediately after extraction to a temperature of around 4 Degrees C and maintaining it at this temperature minimizes further micro-organism growth.Thereby ensuring that milk remains as fresh as it was when extracted.

Bulk Milk Coolers is used to reduce the temperature of the milk for inimizing growth of bacteria which in turn would improve shelf life of the milk.These coolers rapidly cool milk and also ensure that the quality of milk remains high and keeps milk fresh.

In India,NABARD is also offers financial assistance to Indian dairy industry and dairy owners for purchase of bulk milk coolers,which is an added advantage and reason to buy BMCU.

Objectives of having Bulk Milk Cooling Units:

1.To enhance the keeping quality of milk and also to avoid economic losses to farmers due to spillage/sourage of milk.2.To produce improved quality products for export as well as to meet the domestic requirements.3.To reduce the transportation cost by regulating transportation of the milk on alternative days and also through reduction in expenditure on purchase and maintenance of cans.

Thus,BMCUs provides a viable option for reducing the transportation cost as also maintaining the milk quality.Beneficiaries of Bulk Milk Cooling Units (BMCUs) are Milk collection Agents,Village Milk Cooperative Societies of Cooperative Milk Union or Milk Collection Centers of private Dairies.

The operations involve collection and chilling of milk to a temperature of 4 Degrees C.

Advantages of using stainless steel Bulk Milk Cooler or Milk Chillers in modern dairy industry:

1.Elimination of souring/curdling of milk because of cooling at the collection center itself.

2.Adulteration of milk and spillage from cans can be eliminated during transport.

3.Transportation cost of milk can be brought down by regulating transportation to the main dairy either on alternative days or once in a day.

4.Saving of initial investment on purchase of cans and subsequent maintenance cost (Repairs, cleaning etc.) of those cans.

5.Improved quality of milk can be supplied to the main dairy to manufacture quality products for domestic as well as export markets.

6.Flexibility in milk collection time results in increase in volume of milk collected at the centers.

7.Farmers will get better returns for the quality of milk.

8.Chilling at the Main dairy can be avoided.

Economics of buying Bulk Milk Coolers:Based on the various techno commercial parameters,the economics of the purchase of new Bulk Milk Coolers is very positive. The items of income include reduction in souring/curdling of milk, spillage and pilferage of milk, saving of expenditure on transportation, purchase and maintenance of cans and chilling cost received from the union while the expenditure includes the operational cost of cooler (fuel/power), repairs, maintenance and additional manpower.

Krishna Industries,manufacturer of SS Dairy equipments,offers Bulk milk coolers.There Bulk Milk Cooling Units are Dependable and durable,you can count on years of trouble-free performance, the lowest operating costs,precise temperature control,and a wide range of standard features and options.They specialize in milk cooling and storage systems.

Krishna Industries is Leading ISO 9001:2000 Certified manufacturer and exporter of Dairy equipments ,Stainless Steel Milk Cans,Milking Machines,Milk Buckets, Milk Pails, Stainless Steel Milk Cans,Stainless Steel Milk Collection accessories,Bulk Milk Collers.They offer state of the art products in the ever expanding field of Dairy Equipments.They thrive to deliver the highest quality of products that meets the international standards.

Product

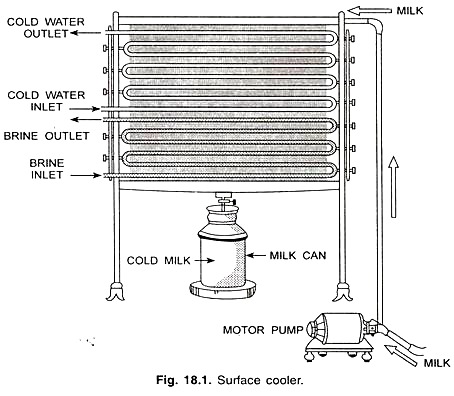

How to Store

Refrigerator (35-40 °F)

Freezer (0 °F)

Pasteurized Fresh Whole or Skimmed Milk

Refrigerate immediately in original container. Keep container closed.

1 to 5 days beyond "sell-by" date

3 months. Freezing may result in change in texture. Thaw in refrigerator.

Sweetened Condensed Milk(Opened)

Refrigerate tightly covered.

1 week

Do not freeze.

Evaporated Milk (Opened)

Refrigerate tightly covered.

1 week

Do not freeze.

Cultured Buttermilk

Refrigerate immediately in original container. Keep container closed.

2 weeks

Do not freeze.

Homogenized, Reconstituted Dry Nonfat and Skimmed Milk

Keep containers tightly closed. Don't return unused milk to original containers.

1 week

Do not freeze.

Sweet and Regular Cream

Refrigerate immediately in original container. Keep container closed.

1 to 5 days beyond "sell-by" date

Do not freeze. (Change of texture, body appearance. Separation of fat emulsion.)

Non-Dairy Whipped Topping

Keep covered.

3 months in aerosol can.

3 days if prepared from mix.

2 weeks if bought frozen and then thawed.

Do not freeze aerosol cans; others may be stored in freezer up to one year.

Butter

Refrigerate immediately in original container. Keep container closed.

2 weeks

Butter made from pasteurized cream: 6 to 9 months.

Sour Cream

Refrigerate immediately in original container. Keep container closed.

2 weeks

Do not freeze.

Ice Cream

Store in original container in freezer.

Do not store here.

2-3 weeks (Opened)

2 months (Unopened)

Yogurt

Keep covered.

7-10 days

Do not freeze.

Soft Custards, Milk Puddings, Cream and Custard Fillings for Cakes and Pies

Cool cooked dishes quickly and refrigerate within 2 hours. Refrigerate cold dishes immediately after preparation.

5-6 days

Do not freeze.

Safe Cold Storage Times for Milk & Dairy Products

Сабақтың жоспары

План урока

Пән

Предмет

Prof. Engl.

Күні

дата

сабақтың №

№ занятия

Топ

группа

Тақырып Тема

Different types of cultured dairy products .

МақсатЦели

Білімділік Дидактическая •to fasten lexical and a writing skills on the topic

Дамытушылық Развивающая to develop monologue speech

ТәрбиелікВоспитывающая to bring up interest in the study of English.

Сабақтын типі (тұрпаты)

Тип урока

Lesson formation of reading skills.

Сабақтын әдісі

Метод обучения

Practical method.Collage.

Корнекілік

Оснащение

Text,tasks

Сабақтын барысы Ход урока

-

Бағдарлану - мотивациялық блок

-

Мотивационно - ориентировочный блок

Сабақтың тақырыбын шығу, жазу

Выход на тему, запись темы урока

Good morning, boys and girls! Nice to meet you! Sit down, please! What can you say about Different types of cultured dairy products?

Оқу мақсатын қою

Постановка цели, задач урока

formation of writing skills.

Сабақтың барысымен танысу

Знакомство с ходом урока

Білім жаңғыртуы

Актуализация знаний

Different types of cultured dairy products .

2. Жана материалды мазмұндау (баяндау) Изложение нового материала

Read and translate: Different types of cultured dairy products .

What is cultured milk? Cultured milks are products made by use of special lactic acid bacteria cultures. They fall into two broad categories. Those made by use of lactic acid bacteria which grow well at ambient temperature (25-30°C). Such lactic acid bacteria are known as Mesophilic starter cultures. Maziwa lala or Mala as it is popularly known in Kenya, is made by use of such cultures. The other type of cultured dairy product is the one made by use of lactic acid bacteria which grow well under warm conditions (38 - 45(C) The lactic acid bacteria used are technically known as Thermophilic starter cultures. Yoghurt or yoghurt like products belong to this group.

Types of cultured milk and starter cultures. As mentioned above, cultured dairy products fall in two broad categories; those made by use of mesophilic starter cultures and those made by use of thermophilic starter cultures. Depending on the type of culture used, the flavour, texture and consistency can vary widely and may be grouped as follows: i) Products made by use of mesophilic lactic starter cultures may use one of the following starter culture types: O-type: These are starter cultures in which the main lactic acid bacteria are Lactococcus lactis subsp.lactis and Lactococcus lactis subsp. cremoris. These produce mainly lactic acid. They are thus, homofermentative. D-type: These are starter cultures containing, in addition to the O-type bacteria also a flavour producing lactic bacteria known as Streptococcus lactis subsp. lactis var. diacetylactis. This, as the name implies, produces a flavour compound known as diacetyl which gives a flavour characteristic of cultured cream butter or its buttermilk by-product. In addition to production of diacetyl, it also produces carbon dioxide which contributes to the blend of a delicate flavour. L-type: This type of starter culture contain, in addition to the O-type bacteria, also Leuconostoc mesenteroides subsp. mesenteroides as the main flavour compound producing bacteria. It produces diacetyl, acetic acid, acetaldehyde and other flavour compounds but less carbon dioxide than the Dtype. LD-type: These contain a combination of Str. lactis subsp. lactis var diacetylactis and Leuconostoc mesenteroides subsp. mesenteroides to give a fine blend of dedicated flavour and aroma. Most "Maziwa lala" products can be made by use of any of these types of lactic starter cultures. They will all give products differing in flavour and texture. Which ever one chooses to use, care should be taken not to use those that lack the desired flavour or those which halve excessive gas production (good for some cheese, but not entirely welcome in good cultured dairy products!). Excessive production of acetaldehyde can also lead to a defect known as "green flavour" more akin to yoghurt than to "Maziwa lala" group of cultured products. ii) Products made by use of thermophilic starter cultures. The main product in this group is yoghurt. The typical lactic acid bacteria in yoghurt starter culture are Streptococcus salivaricus subsp. thermophilus and Lactobacillus delbrueckii subsp. bulgaricus. The former is responsible for fermenting lactose to lactic acid whereas Lb. delbrueckii subsp. bulgaricus is responsible for flavour production, mainly in the form of acetaldehyde. Due to its proven health food qualities, other thermophilic lactic acid bacteria may be included in yoghurt starter cultures to enhance its dietetic and health food status. Lactobacillus acidophilus, which produces a natural antibiotic, acidophilin and Bifidobacterium spp., which are part of the natural bacterial flora of the human gut, are often included in special yoghurt starter cultures. Products such as Bioghurt are made by use of such specially blended cultures and are marketed under the banner of "Health foods" useful for the restoration of normal bacterial flora hollowing a course of oral 3. Рефлексия бақылау блогы Рефлексивно - оценочный блок

Білімдерін бекіту Закрепление знаний

1.What is cultured milk?

2.Types of cultured milk and starter cultures..

Нәтижелерді жинақтап, қортындылау

Обобщение результатов, подведение итогов Conclusion of the lesson.

Рефлексия Collage.

Үй тапсырмасы

Домашнее задание retelling the text

қолы ___________________

подпись ________________

Read and translate: Different types of cultured dairy products .

What is cultured milk? Cultured milks are products made by use of special lactic acid bacteria cultures. They fall into two broad categories. Those made by use of lactic acid bacteria which grow well at ambient temperature (25-30°C). Such lactic acid bacteria are known as Mesophilic starter cultures. Maziwa lala or Mala as it is popularly known in Kenya, is made by use of such cultures. The other type of cultured dairy product is the one made by use of lactic acid bacteria which grow well under warm conditions (38 - 45(C) The lactic acid bacteria used are technically known as Thermophilic starter cultures. Yoghurt or yoghurt like products belong to this group.

Types of cultured milk and starter cultures. As mentioned above, cultured dairy products fall in two broad categories; those made by use of mesophilic starter cultures and those made by use of thermophilic starter cultures. Depending on the type of culture used, the flavour, texture and consistency can vary widely and may be grouped as follows: i) Products made by use of mesophilic lactic starter cultures may use one of the following starter culture types: O-type: These are starter cultures in which the main lactic acid bacteria are Lactococcus lactis subsp.lactis and Lactococcus lactis subsp. cremoris. These produce mainly lactic acid. They are thus, homofermentative. D-type: These are starter cultures containing, in addition to the O-type bacteria also a flavour producing lactic bacteria known as Streptococcus lactis subsp. lactis var. diacetylactis. This, as the name implies, produces a flavour compound known as diacetyl which gives a flavour characteristic of cultured cream butter or its buttermilk by-product. In addition to production of diacetyl, it also produces carbon dioxide which contributes to the blend of a delicate flavour. L-type: This type of starter culture contain, in addition to the O-type bacteria, also Leuconostoc mesenteroides subsp. mesenteroides as the main flavour compound producing bacteria. It produces diacetyl, acetic acid, acetaldehyde and other flavour compounds but less carbon dioxide than the Dtype. LD-type: These contain a combination of Str. lactis subsp. lactis var diacetylactis and Leuconostoc mesenteroides subsp. mesenteroides to give a fine blend of dedicated flavour and aroma. Most "Maziwa lala" products can be made by use of any of these types of lactic starter cultures. They will all give products differing in flavour and texture. Which ever one chooses to use, care should be taken not to use those that lack the desired flavour or those which halve excessive gas production (good for some cheese, but not entirely welcome in good cultured dairy products!). Excessive production of acetaldehyde can also lead to a defect known as "green flavour" more akin to yoghurt than to "Maziwa lala" group of cultured products. ii) Products made by use of thermophilic starter cultures. The main product in this group is yoghurt. The typical lactic acid bacteria in yoghurt starter culture are Streptococcus salivaricus subsp. thermophilus and Lactobacillus delbrueckii subsp. bulgaricus. The former is responsible for fermenting lactose to lactic acid whereas Lb. delbrueckii subsp. bulgaricus is responsible for flavour production, mainly in the form of acetaldehyde. Due to its proven health food qualities, other thermophilic lactic acid bacteria may be included in yoghurt starter cultures to enhance its dietetic and health food status. Lactobacillus acidophilus, which produces a natural antibiotic, acidophilin and Bifidobacterium spp., which are part of the natural bacterial flora of the human gut, are often included in special yoghurt starter cultures. Products such as Bioghurt are made by use of such specially blended cultures and are marketed under the banner of "Health foods" useful for the restoration of normal bacterial flora hollowing a course of oral.

1.What is cultured milk?

2.Types of cultured milk and starter cultures..

Сабақтың жоспары

План урока

Пән

Предмет

Prof. Engl.

Күні

дата

сабақтың №

№ занятия

Топ

группа

Тақырып

Тема

Milk sterilization.

МақсатЦели

Білімділік Дидактическая •to fasten lexical and a writing skills on the topic

Дамытушылық Развивающая to develop monologue speech

ТәрбиелікВоспитывающая to bring up interest in the study of English culture.

Сабақтын типі (тұрпаты)

Тип урока

Lesson formation of writing skills.

Сабақтын әдісі

Метод обучения

Practical method.Collage.

Корнекілік

Оснащение

Text,tasks

Сабақтын барысы Ход урока

1. Бағдарлану - мотивациялық блок

Мотивационно - ориентировочный блок

Сабақтың тақырыбын шығу, жазу

Выход на тему, запись темы урока

Good morning, boys and girls! Nice to meet you! Sit down, please! What can you say about Mechanization in livestock?

Оқу мақсатын қою

Постановка цели, задач урока

formation of writing skills.

Сабақтың барысымен танысу Знакомство с ходом урока

Білім жаңғыртуы

Актуализация знаний

Milk sterilization.

2. Жана материалды мазмұндау (баяндау) Изложение нового материала

Read and translate: Milk sterilization.

The term "sterilization" when used in association with milk, means heating milk in sealed container continuously to a temperature of either 1150C for 15 minutes or at least 1300C for a period of 1 second or more in a continuous flow and then packed under aseptic condition in hermetically sealed containers to ensure preservation at room temperature for a period not less than 15 days from the date of manufacture (FSSA, 2013).

Sterilization of foods by the application of heat can either be in sealed containers or by continuous flow techniques.

Sterilized milk is kept for a long time so that it will show extensive gravity creaming if unhomogenized. Creaming as such is undesirable. Besides, partial coalescence of the closely packed fat globules will lead to formation of a cream plug, which is hard to mix throughout the remaining milk; oiling off may occur at somewhat elevated temperatures. Therefore, sterilized liquid milk is always homogenized.

Advantages:

(i) Remarkable keeping quality; does not need refrigerated storage;

(ii) No cream layer/plug;

(iii) Forms a soft digestible curd, and hence useful for feeding of infants and invalids;

(iv) Distinction rich flavor (due to homogenization);

(v) Economical to use;

(vi) Less liable to develop oxidized taints.

Disadvantage:

(i) increased cost of production;

(ii) More loss in nutritive value than pasteurization

(iii) Gerber test by normal procedure not so accurate.

Sterilized milk must

(i) Keep without deterioration, i.e., remain stable and be of good commercial value for a sufficient period to satisfy commercial requirement

(ii) Be free of any micro-organisms harmful to consumer health, i.e., pathogenic toxinogenic germs and toxins

(iii) Be free of any micro-organisms liable to proliferate, i.e. it should not show signs of bacterial growth (which leads, inter alia, to an absence of deterioration).

In-bottle sterilization

The raw milk, on receipt, should be strictly examined by the physic-chemical and bacteriological test and only high quality milk should be used for production of sterilized milk. Care should be taken to accept milk supplies which have no developed acidity and which contain the least number of spore-forming bacteria. The intake milk should be promptly cooled to 50C for bulk storage in order to check any bacterial growth. Next, it should be pre heated to 35-400C for efficient filtration/ clarification, so as to remove visible dirt, etc., and to increase its aesthetic quality. The milk should again be cooled to 50C so as to preserve its quality. It should then be standardized to the prescribed percentage of fat and solids-not-fat content in order to conform to legal standards. It must be stored at 50C until processing. The milk should be promptly pre heated to 600C for efficient homogenization to prevent any subsequent formation of a cream layer; usually single-stage homogenization is carried out at 2500 psi pressure. The homogenized milk must be clarified so as to remove the sediment formed during the homogenization process. The hot milk from the homogenizer should be filled into the cleaned and sanitized bottle coming from the bottle washing machine and then sealed with special caps. The filled and capped bottles should then be placed in metal crates for sterilization by the batch process, or fed into conveyors for the continuous process. Usually the milk is sterilized at 108-1110C for 25-35 minutes. The sterilized milk bottles should be gradually cooled to room temperature. Any sudden cooling may led to bottle breakage. Finally the milk-in-bottles should be stored in a cool place (De, 2001).

3. Рефлексия бақылау блогы

Рефлексивно - оценочный блок

Білімдерін бекіту Закрепление знаний

2.Advantages-Disadvantage

3.Collage.

Нәтижелерді жинақтап, қортындылау

Обобщение результатов, подведение итогов Conclusion of the lesson.Marks.

Рефлексия Collage.

Үй тапсырмасы

Домашнее задание table

қолы ___________________

подпись ________________

The term "sterilization" when used in association with milk, means heating milk in sealed container continuously to a temperature of either 1150C for 15 minutes or at least 1300C for a period of 1 second or more in a continuous flow and then packed under aseptic condition in hermetically sealed containers to ensure preservation at room temperature for a period not less than 15 days from the date of manufacture (FSSA, 2013).

The term "sterilization" when used in association with milk, means heating milk in sealed container continuously to a temperature of either 1150C for 15 minutes or at least 1300C for a period of 1 second or more in a continuous flow and then packed under aseptic condition in hermetically sealed containers to ensure preservation at room temperature for a period not less than 15 days from the date of manufacture (FSSA, 2013).

Sterilization of foods by the application of heat can either be in sealed containers or by continuous flow techniques.

Sterilized milk is kept for a long time so that it will show extensive gravity creaming if unhomogenized. Creaming as such is undesirable. Besides, partial coalescence of the closely packed fat globules will lead to formation of a cream plug, which is hard to mix throughout the remaining milk; oiling off may occur at somewhat elevated temperatures. Therefore, sterilized liquid milk is always homogenized.

Advantages:

(i) Remarkable keeping quality; does not need refrigerated storage;

(ii) No cream layer/plug;

(iii) Forms a soft digestible curd, and hence useful for feeding of infants and invalids;

(iv) Distinction rich flavor (due to homogenization);

(v) Economical to use;

(vi) Less liable to develop oxidized taints.

Disadvantage:

(i) increased cost of production;

(ii) More loss in nutritive value than pasteurization

(iii) Gerber test by normal procedure not so accurate.

Sterilized milk must